2205 Duplex Stainless Steel Plate | High-Strength & Corrosion Resistant

Sandmeyer Steel Company has an extensive inventory of 2205 duplex stainless steel plate in thicknesses from 3/16″ (4.8mm) through 6″ (152.4mm). The yield strength is about twice that of austenitic stainless steels, thus allowing a designer to save weight and making the alloy more cost competitive when compared to 316L or 317L.

Available thicknesses for Alloy 2205:

| 3/16" | 1/4" | 5/16" | 3/8" | 1/2" | 5/8" | 3/4" | 7/8" | 1" | 1 1/8" | 1 1/4" | 1 3/8" | 1 1/2" |

| 4.8mm | 6.3mm | 7.9mm | 9.5mm | 12.7mm | 15.9mm | 19mm | 22.2mm | 25.4mm | 28.6mm | 31.8mm | 34.9mm | 38.1mm |

| 1 5/8" | 1 3/4" | 2" | 2 1/4" | 2 1/2" | 2 3/4" | 3" | 3 1/4" | 3 1/2" | 4" | 5" | 6" | |

| 41.3mm | 44.5mm | 50.8mm | 57.2mm | 63.5mm | 69.9mm | 76.2mm | 82.6mm | 88.9mm | 101.6mm | 127mm | 152.4mm |

Alloy 2205 (UNS S32305/S31803) is a 22% chromium, 3% molybdenum, 5-6% nickel, nitrogen alloyed duplex stainless steel plate with high general, localized, and stress corrosion resistance properties in addition to high strength and excellent impact toughness.

Alloy 2205 duplex stainless steel plate provides pitting and crevice corrosion resistance superior to 316L or 317L austenitic stainless steels in almost all corrosive media. It also has high corrosion and erosion fatigue properties as well as lower thermal expansion and higher thermal conductivity than austenitic.

Specification Sheet Overview

for Alloy 2205 (UNS S32205/S31803)

A 22Cr-3Mo Stainless Steel:

General Properties

Alloy 2205 duplex stainless steel plate is a 22% Chromium, 3% Molybdenum, 5-6% Nickel nitrogen alloyed duplex stainless steel plate with high general, localized and stress corrosion resistance properties in addition to high strength and excellent impact toughness.

Alloy 2205 duplex stainless steel plate provides pitting and crevice corrosion resistance superior to 316L or 317L austenitic stainless steels in almost all corrosive media. It also has high corrosion and erosion fatigue properties as well as lower thermal expansion and higher thermal conductivity than austenitic.

The yield strength is about twice that of austenitic stainless steels. This allows a designer to save weight and makes the alloy more cost competitive when compared to 316L or 317L.

Alloy 2205 duplex stainless steel plate is particularly suitable for applications covering the -50°F/+600°F temperature range. Temperatures outside this range may be considered but need some restrictions, particularly for welded structures.

Applications

- Pressure vessels, tanks, piping, and heat exchangers in the chemical processing industry

- Piping, tubing, and heat exchangers for the handling of gas and oil

- Effluent scrubbing systems

- Pulp and paper industry digesters, bleaching equipment, and stock-handling systems

- Rotors, fans, shafts, and press rolls requiring combined strength and corrosion resistance

- Cargo tanks for ships and trucks

- Food processing equipment

- Biofuels plants

Corrosion Resistance

General Corrosion

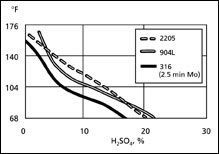

Because of its high chromium (22%), molybdenum (3%), and nitrogen (0.18%) contents, the corrosion resistance properties of 2205 duplex stainless steel plate are superior to that of 316L or 317L in most environments.

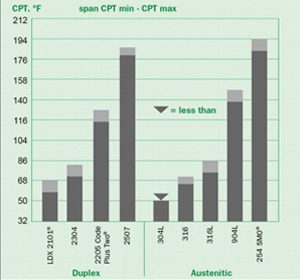

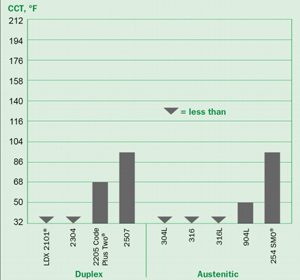

Localized Corrosion Resistance

The chromium, molybdenum, and nitrogen in 2205 duplex stainless steel plate also provide excellent resistance to pitting and crevice corrosion even in very oxidizing and acidic solutions.

Isocorrosion Curves 4 mpy (0.1 mm/yr), in sulfuric acid solution containing 2000 ppm

Stress Corrosion Resistance

The duplex microstructure is known to improve the stress corrosion cracking resistance of stainless steels.

Chloride stress corrosion cracking of austenitic stainless steels can occur when the necessary conditions of temperature, tensile stress, oxygen, and chlorides are present. Since these conditions are not easily controlled, stress corrosion cracking has often been a barrier to utilizing 304L, 316L, or 317L.

Corrosion Fatigue Resistance

Alloy 2205 duplex stainless steel plate combines high strength and high corrosion resistance to produce high corrosion fatigue strength. Applications in which processing equipment is subject to both an aggressively corrosive environment and to cycle loading can benefit from the properties of 2205 duplex stainless steel plate.

Critical Pitting Temperature in 1M NaCl Measured using the Outokumpu Stainless, Inc Pitting Cell

Critical Crevice Corrosion Temperature (CCT) in 10% FeCl3•6H2O

General Corrosion in Wet Process Phosphoric Acids

Stress Corrosion Cracking Resistance

| Boiling | Wick | Boiling | |

|---|---|---|---|

| Grade | 42% MgCl2 | Test | 25% NaCl |

| 2205 | F | P | P |

| 254 SMO® | F | P | P |

| Type 316L | F | F | F |

| Type 317L | F | F | F |

| Alloy 904L | F | P or F | P or F |

| Alloy 20 | F | P | P |

(P = Pass, F = Fail)

Chemical Analysis

Typical Values (Weight %)

| Carbon | Chromium | Nickel | Molybdenum | Nitrogen | Others |

|---|---|---|---|---|---|

| 0.020 | 22.1 | 5.6 | 3.1 | 0.18 | S=0.001 |

Mechanical Properties

Mechanical Properties at Room Temperature

| ASTM A 240 | Typical | |

|---|---|---|

| Yield Strength 0.2%, ksi | 65 min. | 74 |

| Tensile Strength, ksi | 90 min. | 105 |

| Elongation, % | 25 min. | 30 |

| Hardness RC | 32 max. | 19 |

Tensile Properties at Elevated Temperatures

| Temperature °F | 122 | 212 | 392 | 572 |

|---|---|---|---|---|

| Yield Strength 0.2%, ksi | 60 | 52 | 45 | 41 |

| Tensile Strength, ksi | 96 | 90 | 83 | 81 |

Physical Properties

| Temperature °F | 68 | 212 | 392 | 572 | |

|---|---|---|---|---|---|

| Density | lb/in3 | 0.278 | — | — | — |

| Modulus of Elasticity | psi x 106 | 27.6 | 26.1 | 25.4 | 24.9 |

| Linear Expansion (68°F-T) | 10-6/°F | — | 7.5 | 7.8 | 8.1 |

| Thermal Conductivity | Btu/h ft°F | 8.7 | 9.2 | 9.8 | 10.4 |

| Heat Capacity | Btu/lb ft°F | 0.112 | 0.119 | 0.127 | 0.134 |

| Electrical Resistivity | Ωin x 10-6 | 33.5 | 35.4 | 37.4 | 39.4 |

Structure

The chemical analysis of 2205 duplex stainless steel plate is optimized to obtain a typical 50 a/ 50 g microstructure after solution annealing treatment at 1900°/1922°F (1040°/1080°C).

Chloride Pitting Resistance

The pitting resistance of an austenitic stainless steel can be related directly to alloy composition, where chromium, molybdenum and nitrogen are a weight %. The Pitting Resistance Equivalent Number (PREN) uses the following formula to measure an alloy’s relative pitting resistance – the higher the number, the better the pitting resistance.

Processing

Hot Forming

Forming below 600°F is recommended whenever possible. When hot forming is required, the workpiece should be heated uniformly and worked in the range of 1750 to 2250°F. Alloy 2205 duplex stainless steel plate is quite soft at these temperatures and is readily formed. Above this range, 2205 is subject to hot tearing. Immediately below this range, the austenite becomes substantially stronger than the ferrite and may cause cracking, a particular danger to “cold” edges. Below 1700°F there can be rapid formation of intermetallic phases because of the combination of temperature and deformation. Whenever hot forming is done, it should be followed by a full solution anneal at 1900°F minimum and rapid quench to restore phase balance, toughness, and corrosion resistance. Stress relieving is not required or recommended; however, if it must be performed, the material should receive a full solution anneal at 1900°F minimum, followed by rapid cooling or water quenching.

Cold Forming

Alloy 2205 duplex stainless steel plate is readily sheared and cold formed on equipment suited to working stainless steels. However, because of the high strength and rapid work hardening of 2205 duplex stainless steel plate, forces substantially higher than those for austenitic steels are required to cold form it. Also because of the high strength, a somewhat larger allowance must be made for spring back.

Heat Treatment

Alloy 2205 duplex stainless steel plate should be annealed at 1900°F minimum, followed by rapid cooling, ideally by water quenching. This treatment applies to both solution annealing and stress relieving. Stress relief treatments at any lower temperature carry the risk of precipitation of detrimental intermetallic or nonmetallic phases.

Machinability

With high-speed steel tooling, 2205 duplex stainless steel plate may be machined at the same feeds and speeds as Alloy 316L. When carbide tooling is used, cutting speeds should be reduced by about 20% relative to the speeds for Alloy 316L. Powerful machines and rigid mounting of tools and parts are essential.

Welding

Alloy 2205 duplex stainless steel plate possesses good weldability. The goal of welding 2205 is that the weld metal and heat-affected zone (HAZ) retain the corrosion resistance, strength, and toughness of the base metal. The welding of 2205 is not difficult, but it is necessary to design welding procedures that lead to a favorable phase balance after welding and will avoid precipitation of detrimental intermetallic or nonmetallic phases.

Alloy 2205 duplex stainless steel plate can be welded by: GTAW (TIG); GMAW (MIG); SMAW (“stick” electrode); SAW; FCW; and PAW.

Alloy 2205 Duplex Stainless Steel – Frequently Asked Questions

1. What is Alloy 2205 stainless steel?

Alloy 2205 (UNS S32205) is a nitrogen-enhanced duplex stainless steel developed to combat common corrosion problems with 300 series stainless steels. It combines improved resistance to pitting, crevice corrosion, and stress-corrosion cracking with higher strength than austenitic stainless grades like 304 and 316.

2. What applications are suited for 2205 plate?

Due to its high strength and corrosion resistance, Alloy 2205 is commonly used in:

• Heat exchangers

• Pressure vessels

• Chemical processing equipment

• Marine and offshore structures

• Pulp and paper industry components

• Desalination plants

• Storage tanks and piping systems

3. What mechanical properties does 2205 offer?

Typical mechanical properties for Alloy 2205 at room temperature:

• Yield Strength (0.2% offset): 65 ksi

• Tensile Strength: 95–115 ksi

• Elongation in 2″: ≥25%

• Hardness: ≤293 HB (Brinell)

This strength is approximately twice that of standard austenitic stainless steels.

4. What are the physical properties of 2205 duplex stainless steel?

• Density: 0.278 lb/in³

• Thermal Conductivity: 8.7 BTU/hr·ft·°F

• Specific Heat: 0.11 BTU/lb·°F

• Modulus of Elasticity: 27.6 x 10⁶ psi

• Electrical Resistivity: 33.5 µΩ·cm at 68°F

5. How resistant is 2205 to corrosion?

2205 provides excellent resistance to:

• Pitting and crevice corrosion, thanks to its high chromium, molybdenum, and nitrogen content

• Chloride stress-corrosion cracking, superior to 304 and 316

• General corrosion in harsh environments such as marine, chemical, and acidic process conditions

6. Is 2205 duplex stainless weldable?

2205 duplex stainless steel can be welded using most standard techniques. Proper procedures should be followed to maintain corrosion resistance and mechanical strength, including pre-weld cleaning, interpass temperature control, and post-weld inspection. Use of filler metals compatible with duplex stainless steels is recommended to ensure weld integrity.

7. What are the specifications for Alloy 2205?

• ASTM/ASME………..A240 / SA 240 UNS S32205/S31803

• EURONORM………..1.4462 X2CrNiMoN 22.5.3

• AFNOR……………….Z3 CrNi 22.05 AZ

• DIN…………………….W. Nr 1.4

9. Is 2205 a good alternative to 316L?

Yes. In many environments, 2205 provides better corrosion resistance, greater strength, and longer service life than 316L, especially in chloride-rich or acidic environments.

10. What thicknesses of Alloy 2205 does Sandmeyer Steel Company stock?

Sandmeyer Steel stocks Alloy 2205 stainless steel plate in thicknesses from 3/16″ (4.8 mm) through 6″ (152.4 mm).