Alloy 904L Stainless Steel Plate – Superior Corrosion Resistance for Harsh Environments

Sandmeyer Steel Company stocks Alloy 904L stainless steel plate in thicknesses from 3/16″ through 2″. Alloy 904L (UNS N08904) is a superaustenitic stainless steel designed for corrosion and pitting resistance in a wide range of process environments. It is used extensively in the chemical process industry including the production of phosphate-based fertilizers.

Available thicknesses for Alloy 904L:

| 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" |

| 4.8mm | 6.3mm | 9.5mm | 12.7mm | 15.9mm | 19mm |

| 1" | 1 1/4" | 1 1/2" | 1 3/4" | 2" | |

| 25.4mm | 31.8mm | 38.1mm | 44.5mm | 50.8mm |

Specification Sheet Overview

for Alloy 904L (UNS N08904)

W. Nr. 1.4539:

General Properties

Alloy 904L (UNS N08904) is a superaustenitic stainless steel that is designed for moderate to high corrosion resistance in a wide range of process environments. The combination of high chromium and nickel content, coupled with additions of molybdenum and copper, assure good to excellent corrosion resistance.

With its highly alloyed chemistry — 25% nickel and 4.5% molybdenum, 904L provides good chloride stress corrosion cracking resistance, pitting and general corrosion resistance superior to 316L and 317L molybdenum enhanced stainless steels.

Alloy 904L was originally developed to withstand environments containing dilute sulfuric acid. It also offers good resistance to other inorganic acids such as hot phosphoric acid as well as most organic acids.

Alloy 904L is easily welded and processed by standard shop fabrication practices.

Applications

- Air Pollution Control — scrubbers for coal-fired power plants

- Chemical Processing — process equipment for the production of sulfuric, phosphoric, inorganic and organic acids and the production of phosphate-based fertilizers

- Metallurgical Processing — pickling equipment using sulfuric acid

- Oil and Gas Production — offshore process equipment

- Pharmaceutical Industry — process equipment

- Pulp and Paper — processing equipment

- Seawater and Brackish Water — condensers, heat exchangers and piping systems

Corrosion Resistance

The high content of alloying elements in 904L gives the alloy exceptionally good resistance to uniform corrosion.

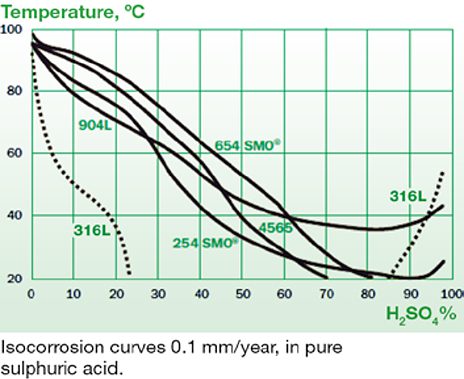

904L was originally developed to withstand environments containing dilute sulfuric acid, and is one of the few stainless steels that, at temperatures up to 95°F (35°C), provides full resistance in such environments within the entire concentration range of 0 to 100%. 904L also offers good resistance to a number of other inorganic acids, such as phosphoric acid and most organic acids. However, acids and acid solutions containing halide ions can be very aggressive, and the corrosion resistance of 317L, 317LMN and 904L may be insufficient.

Fractional distillation of tall oil often needs better material than 316L or even the more frequently used 317LMN. In these hot concentrated caustic solutions, the corrosion resistance is mainly determined by the nickel content of the material. With a nickel content of 25%, 904L has proven to be a good alternative to most conventional stainless steels.

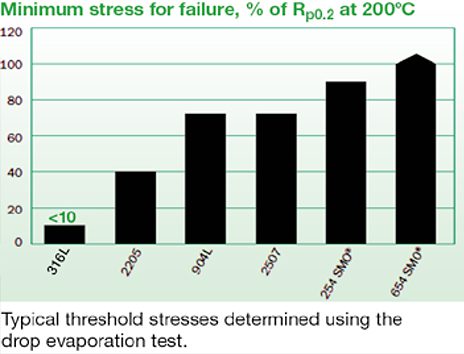

Conventional stainless steels such as 304L and 316L are susceptible to chloride stress corrosion cracking (SSC) under certain conditions. Resistance to SSC increases with the increased content of nickel and molybdenum. Therefore, the higher performance austenitic stainless steels such as 904L have very good resistance to SSC. The table in the upper right corner shows resistance to SSC in a chloride solution under evaporative conditions. High performance austenitic steels and duplex stainless steels clearly outperform 316L.

Uniform Corrosion in pickling acid* at 25°C

| ALLOY | Corrosion Rate, mm/year |

|---|---|

| 316L | >6 |

| 904L | 0.47 |

| 254 SMO® | 0.27 |

| 654 SMO® | 0.06 |

*Composition: 20% HNO3 + 4 HF.

Uniform Corrosion in wet process phosphoric acid at 60°C

| ALLOY | Corrosion Rate, mm/year |

|---|---|

| 316L | >5 |

| 904L | 1.2 |

| 254 SMO® | 0.05 |

Composition: 54% P2O5, 0.06% HCI, 1.1% HF, 4,0% H2SO4, 0.27% Fe2O3, 0.17% AI2O3, 0.10% SiO2, 0.20% CaO and 0.70% MgO.

Corrosion rates in fatty acid column for the distillation of tall oil at 253°C

| ALLOY | Corrosion Rate, mm/year |

|---|---|

| 316L | 0.88 |

| 317LMN | 0.29 |

| 904L | 0.056 |

| 254 SMO® | 0.01 |

Chemical Analysis

Weight % (all values are maximum unless a range is otherwise indicated)

| Nickel | 23.0 min.-28.0 max. | Silicon | 1.00 |

| Chromium | 19.0 min.-23.0 max. | Phosphorus | 0.045 |

| Molybdenum | 4.0 min.-5.0 max. | Sulfur | 0.035 |

| Copper | 1.0-2.0 max. | Iron | Balance |

| Manganese | 2.00 |

Density

0.287 lbs/in3

7.95 g/cm3

Specific Heat

0.11 BTU/lb-°F (32 – 212°F)

450 J/kg-°K (0 – 100°C)

Modulus of Elasticity

28.0 x 106 psi

190 GPa

Thermal Conductivity 212°F (100°C)

6.8 BTU/Ft-hr°F

12.9 W/m-°K

Melting Range

2372 – 2534°F

1300 – 1390°C

Electrical Resistivity

33.5 Microhm-in at 68°C

95.2 Microhm-cm at 20°C

Mean Coefficient of Thermal Expansion

| °F | °C | in/in °F | cm/cm °C |

| 68-212 | 20-100 | 8.5 x 10-6 | 15.3 x 10-6 |

Mechanical Properties

Typical Values at 68°F (20°C) (minimum values, unless specified)

0.2% Offset | Strength | in 2 in. | |||

|---|---|---|---|---|---|

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 31,000 | 220 | 71,000 | 490 | 36 | 70-90 Rockwell B |

Fabrication Data

Alloy 904L can be easily welded and processed by standard shop fabrication practices.

Cold Forming

904L is quite ductile and forms easily. The addition of molybdenum and nitrogen implies more powerful processing equipment may be necessary when compared with the standard 304/304L grades.

Hot Forming

Working temperatures of 1562 – 2102°F (850 –1150°C) are recommended for hot working processes. Normally hot working should be followed by a solution anneal and quench, but for 904L, if hot forming is discontinued at a temperature above 2012°F (1100°C) and the material is quenched directly thereafter, the material may be used without subsequent heat treatment. It is important that the entire workpiece be quenched from temperatures above 2012°F (1100°C). In the event of partial heating or cooling below 2012°F (1100°C), or if the cooling has been too slow, hot working should always be followed by a solution anneal and quenching. 904L should be solution annealed at 1940 – 2084°F (1060 –1140°C).

Machining

The cold work hardening rate of Alloy 904L makes it less machinable than 410 and 304 stainless steels.

Welding

Alloy 904L can be readily welded by most standard processes. Austenitic plate materials have a homogeneous austenitic structure with an even distribution of alloying elements. Solidification after welding causes the redistribution of certain elements such as molybdenum, chromium and nickel. These segregations remain in the cast structure of the weld and can impair the corrosion resistance in certain environments. Segregation is less evident in 904L, and this material is normally welded using a filler metal of the same composition as the base metal and can even be welded without filler metal.

The welding consumables for 904L are 20 25 CuL covered electrode and 20 25 CuL wire.

Alloy 904L Stainless Steel – Frequently Asked Questions

1. What is Alloy 904L stainless steel?

Alloy 904L (UNS N08904) is a superaustenitic stainless steel containing high levels of chromium, nickel, molybdenum, and copper. It was originally developed for resistance to dilute sulfuric acid and offers exceptional resistance to a wide range of corrosive environments, including chlorides, phosphoric acid, and organic acids.

2. What are typical applications for Alloy 904L?

904L stainless steel is used in environments requiring superior corrosion resistance, including:

• Air pollution control systems (e.g., scrubbers)

• Chemical processing of sulfuric and phosphoric acid

• Phosphate-based fertilizer production

• Offshore oil and gas platforms

• Pharmaceutical and food processing equipment

• Seawater heat exchangers and brackish water piping

• Pickling equipment in metallurgical plants

3. How does Alloy 904L perform in corrosive environments?

Alloy 904L offers superior resistance to uniform corrosion, pitting, crevice corrosion, and chloride-induced stress corrosion cracking (SCC). It outperforms 316L and 317LMN in sulfuric acid, phosphoric acid, and fatty acid environments.

4. What are the mechanical properties of Alloy 904L stainless steel?

Typical values at 68°F (20°C):

• Yield Strength (0.2% offset): 31,000 psi (220 MPa)

• Ultimate Tensile Strength: 71,000 psi (490 MPa)

• Elongation in 2″: 36% minimum

• Hardness: 70–90 Rockwell B

5. What are the physical properties of Alloy 904L?

• Density: 0.287 lbs/in³ (7.95 g/cm³)

• Specific Heat: 0.11 BTU/lb-°F

• Modulus of Elasticity: 28.0 × 10⁶ psi (190 GPa)

• Thermal Conductivity at 212°F: 6.8 BTU/hr/ft²/ft/°F

• Electrical Resistivity: 33.5 Microhm-in

• Mean Coefficient of Expansion (68–212°F): 8.5 × 10⁻⁶ in/in-°F

• Melting Range: 2372–2534°F (1300–1390°C)

6. Is Alloy 904L magnetic?

No. Alloy 904L is non-magnetic in all conditions, even after cold working or welding.

7. Can Alloy 904L be welded and fabricated?

Yes. 904L is readily welded using standard processes and filler metals such as 20 25 CuL. Its high alloy content results in minimal segregation during solidification, preserving corrosion resistance. It is also easily formed, though its strength may require more robust equipment compared to 304 or 316.

8. How does Alloy 904L compare to 316L and 317LMN in real-world performance?

Alloy 904L provides significantly better performance in aggressive acids, chloride-containing environments, and elevated-temperature service. In tests, it showed corrosion rates of:

• 0.47 mm/year in pickling acid vs. >6 for 316L

• 1.2 mm/year in phosphoric acid vs. >5 for 316L

• 0.056 mm/year in tall oil distillation vs. 0.88 for 316L and 0.29 for 317LMN

9. What standards apply to Alloy 904L stainless steel?

• ASTM……..A 240

• ASME……..SA 240

• AMS……….5521

• QQ-S………766

10. What thicknesses of Alloy 904L plate does Sandmeyer Steel stock?

Sandmeyer Steel stocks Alloy 904L stainless steel plate in thicknesses ranging from 3/16″ (4.8 mm) through 2″ (50.8 mm).