At Sandmeyer Steel, no job is too large or too small. We pride ourselves on delivering custom-cut stainless steel components with unmatched precision and speed. Pictured here is a large cut piece made from 304…

Here’s a look at a recent custom-cut job featuring two pieces of 1 1/2” thick 304 stainless steel, cut precisely to our customer’s specifications. Thanks to our extensive on-site inventory and advanced in-house processing capabilities,…

As part of our Sandmeyer Serves program of volunteer activity, employees recently donated their time to local organization Cathedral Kitchen in Camden, NJ. Cathedral Kitchen serves nutritious meals for impoverished residents of Camden, and served 100,000…

Our customer required four type 304 heat exchanger baffles, each 1/2” thick with a 40” OD. The baffles feature 5/8” diameter holes drilled for speed and efficiency, utilizing Sandmeyer Steel’s new Quickmill Annihilator. This advanced…

This recent project was completed for a customer in the thermal processing equipment industry. The piece is 9′ long and made from Alloy 800, featuring a precision beveled edge, cut on our advanced waterjet machine….

This image shows the top and bottom of a recently completed project which involved a multi-step process. First, the component underwent rough machining to shape the outer and inner diameters, removing a significant portion of…

Here is a recent example of a job we shipped out to our customer. With our vast in-house plate processing capabilities, Sandmeyer is able to cut special shapes with speed and accuracy, including intricate and…

Here is an image of a part of a recent order we shipped for a pressure vessel component manufacturer. They required 304H plate in a variety of thicknesses and widths of up to 120″. We…

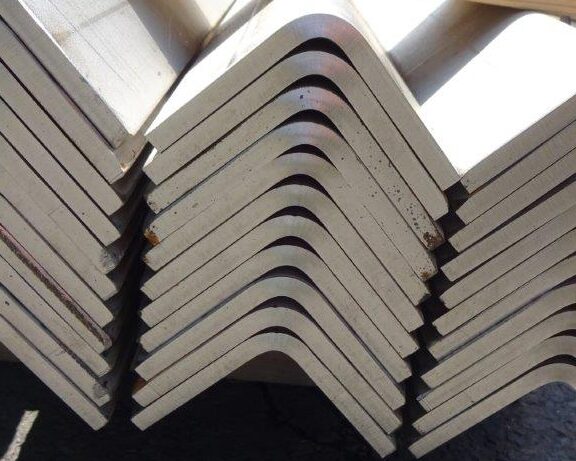

Below are some shots of a recent job that we formed from 317L. In addition to forming, see our extensive list of processing capabilities here.